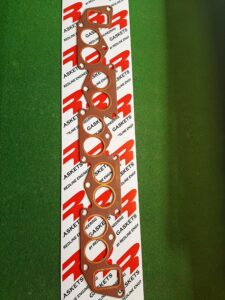

Austin Healey cylinder head gasket

AUSTIN HEALEY cylinder head gasket

Various thicknesses available.

Superior Quality reusable cylinder head gasket

Intake / Exhaust quality manifold gasket

AVOID

BLOWN Gasket … Water in oil

BLOWN Gasket … Oil in Water

BLOWN Gasket … Compression in water system

BLOWN Gasket … Cracked cylinder head and or cylinder Block

BLOWN Gasket … Warped cylinder head and or cylinder Block

BLOWN Gasket … Misfire on one or multiple cylinders

BLOWN Gasket … Excessive white smoke from tailpipe

BLOWN Gasket … Engine overheating

BLOWN Gasket … Engine does not start, hydraulic lock

BLOWN Gasket … Water leaks in radiator, hoses, Freeze plugs

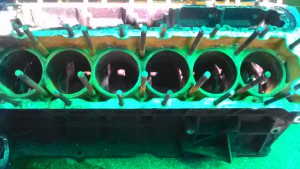

Blown head gasket

This is an extreme example of a blown head gasket.

Most gaskets are designed, to do their job of sealing about 100bar cylinder pressure within each cylinder, and at the same time keeping oil (7bar @ WOT) and water (2bar @ WOT) from mixing.

This is already quite a lot to ask.

Higher compression engines, either normally aspirated or some form of forced induction (when under boost) can require more work to ‘tune out’ DETONATION. Once detonation sets on, cylinder pressures and temperatures escalate rapidly. Pressures up to 8 times normal cylinder pressure, sometimes even more, cause the cylinder head to literally lift up leaving the cylinder head gasket unclamped.

Production gaskets will let go under these conditions every time, just like the example shown. It is important to note here that no engine should ever be run under these adverse conditions purposely, however during the ‘tuning’ period of many performance engines these severe conditions may be encountered for short periods, so it is vital to have a cylinder head gasket that can withstand brief bursts of detonation without letting go, so that further adjustments can be made to “tune out” any detonation spikes.

Many factors can creep in even with an already ‘tuned’ engine, leading to detonation. Low octane (a bad tank of fuel) is often a danger especially in a vehicle without a closed loop oxygen sensor.

South Africa still has a RON (research octane number) fuel rating, unlike some first World countries, who indicate fuel rating using PON (pump octane number). PON is the average of RON and MON (motor octane number). PON = (RON + MON) / 2

PON is a much more accurate and ‘STABLE’ way to rate fuel octane, as the MON value, which is of more importance, cannot drop off too severely.

Example: USA (95RON + 83MON) / 2 = 89 PON

RSA (95RON + Fluctuating) / 2 = DAMAGE

It is important to know what ‘OCTANE’ you are getting for your performance engine.

Generally performance engines don’t use pump fuel anyway.

Iso octane has both RON and MON of 100 and is used as the reference fuel in octane testing. Any fuel with an octane rating of 90 performs like a test fuel of 90% Iso octane 10% n-heptane.

When fuels are more than 100% resistant or more resistant than Iso octane, which was given value of 100 then the fuel can be rated using SON octane scale.

SON (Supercharged Octane Number) allows for fuel octane numbers over 100.

Cars with closed loop O2 sensors can often pull timing when running on bad fuel giving the vehicle a sluggish feel.

It should also be noted that modern pump fuel can last as little as 40days, under poor circumstances, before all the volatiles evaporate off. By 160days, you have fuel for your lawnmower.

Another cause of a blown head gasket is excessive ignition timing.

Different engines with differing combustion chamber characteristics require a different amount of advance and total timing. Older 2 valve engines require more ignition timing. Hemispherical type chamber may need 40′ – 44′ of total timing. Bathtub / Heart type combustion chambers 33′ – 36′ of total timing. Wedge and double hemispherical 35′ – 38′ total timing. Modern Pent Roof type combustion chambers rely far less on squish with 4 valves per cylinder require 28′ – 32′ of total timing and some 5 valve per cylinder engines as little as 26′ total timing.

If you have an engine that relies on squish and you have fitted a shim plate because your head has been “over skimmed” to both lower the compression ratio and prevent valve contact, you also need to run less total timing.

Too much of a good thing…

As a result of the cylinder head being skimmed beyond the recommended maximum, the need to lower the static compression ratio back to standard is often overlooked by engineering shops, which leads to premature failure of the new head gasket.

The following does not apply to ‘Old style’ VW Beetle, Porsche (Aircooled) or any other aircooled engines.

Perhaps the most common cause of a blown head gasket is through overheating due to loss of coolant. Corrosion around the water passages of either cylinder head or block can allow water to enter the combustion chamber just to be consumed and exit out the exhaust. Water hoses fail, often just behind their hose clamp, allowing external coolant loss which can be slow and gradual or very sudden. Metal water pipes as well as welsh plugs can corrode through creating ‘pin holes’ allowing coolant leaks.

Thermostats can jam up in the nearly closed position preventing sufficient flow in the cooling system. Many mechanics think they are solving a overheating problem by removing the thermostat, and in doing so often get a lower temperature reading on the temperature gauge. What is being shown on the temperature gauge, the water is circulating through the radiator only, via the bypass passage, which is no longer closed because of the removal of the thermostat on certain engines. Very little of the motors heat is absorbed into this water. What is not shown on the temperature gauge is that the water in the cylinder head is boiling, as it is not being cooled by the water flowing through the radiator only. Large steam pockets often form around the hottest area, the exhaust valves, causing localised overheating where cracks can form from the exhaust seats to the adjacent water ways. This localised overheating will also cause the engine to detonate and more often than not blow the head gasket if not remedied.

Water pumps, either metal bladed or plastic bladed can “lose” their impellers so that coolant circulation ceases to exist.

When a loss of circulation or a coolant loss occurs it often does not show up on the temperature gauge, as the thermister is often mounted in an unfavourable position, where once a small coolant loss occurs it is no longer surrounded by the coolant and therefore does not indicate the correct coolant temperature.

Radiators over the years can become far less efficient (70%) or more due to their internal passages becoming blocked. Never assume that just because your radiator is not leaking that it is in 100% working order. A new radiator is a good investment unless you know a reputable radiator repair shop.

Very old vehicles had open or non pressurised cooling systems. The car engines we know all have pressurised cooling systems. Radiator caps generally have blow off pressures between 1bar and 2 bar.

Increasing the allowable pressure in the cooling system allows the coolant to exceed 100 degrees c before it boils. The higher the pressure in the system, the higher the point at which the coolant will boil. If you leave the cap off the coolant may well boil over, like a pan of boiling water on the stove, leaving little coolant to cool your engine. So make sure your radiator cap stays on!

A water pressure gauge can be a useful add on. It should be scaled to read from 0 – 2.5bar.

Viscous or clutch type fans can become faulty or only work intermittently as can an electric fans temperature switch.

Fan belts remnants are often found along the roadside reminding us that most car parts are NOT made to last forever.

Remember that ‘Antifreeze’ should be labeled ANTICORROSIVE as many people living in a hot climate are misled, thinking that they do not require this “special” coolant in their cars. In fact they do NOT. All they need is water and a rust inhibitor, or a sacrificial ANODE. The anode can be zinc or aluminium in a cast iron engine, and zinc but preferably magnesium in a partial or full aluminium engine. All this said, antifreeze has no place in a HOT climate, or in any performance engine. Without going into too much detail, water has a far higher heat capacity than that of antifreeze. The higher the percentage of antifreeze the lower the specific heat capacity of the liquid and the lower is the heat transference both from metal to liquid as well as from liquid to air. Modern vehicles use thermostats in conjunction with electric or temperature activated fans so the cooling system works at a regulated temperature, the gauge is not really showing what is happening around the combustion chamber which is of the most importance. The position of the THERMISTOR (calibrated temperature gauge sender unit) is positioned at a point where the coolant temperature has already been regulated by the thermostat and hard working fans, and is not at all a indication of the temperature directly around your combustion chamber. Water conducts heat away from the combustion chamber a lot more efficiently than antifreeze, so the cylinder head temperature is considerably lower using water thereby reducing the risk of DETONATION.

We have conducted extensive tests on this subject to validate these findings.

Some engines have “loose” sleeves or removable sleeves. These slide in by hand and often use some kind of gasket on their flange surface. The area where these sleeves meet the block is often corroded away or badly pitted. This destroys any chance of a good seal and oil and water will mix.

Another problem area of “loose” sleeve engines is checking the sleeve protrusion relative to the cylinder block surface. Usually the sleeves should be above the block surface by around 2 hundredths of a millimeter, but often one or many of the sleeves are at a different height. This will cause head gasket sealing issues and again water in the oil, which turns the oil milky.

There are in fact too many reasons or causes of blown head gaskets but most of them are listed above. Excessive white smoke from the exhaust is usually a sign of coolant being burnt in the combustion chamber due to a bad head gasket. White smoke can also be a crack in the cylinder heads exhaust port, losing coolant directly into the exhaust manifold. A blown head gasket can give you water in the oil, where the oil becomes a milky tan colour. Oil in the cooling system can also occur depending on the pressure differential, where the radiator cap gets oil coagulating on it. Compression pressure in the cooling system is a classic sign of a blown head gasket. It can be so severe that it will blow hoses off or apart, push coolant past the radiator cap, crack a plastic expansion bottle, dislodge a welch plug or even detonate a radiator. It will find the weakest spot, and blow the coolant out.

It is this loss of coolant that causes overheating and further engine damage.

Check and maintain your cooling system on a regular basis

Austin Austin Healey Austin Healey 3000